Direct Uv 3d Fine Art Print

Our large-format flatbed printer, equipped with Epson's 10-ink UltraChrome UV technology, enables high-resolution printing on a diverse array of materials, extending beyond traditional substrates like Dibond and Forex.

By adding a third dimension to the printing surface, we can create works that can also be experienced through the sense of touch.

These tactile pieces can be safely handled by the public without risk of damage, thanks to the exceptional durability of this printing technique.

Moreover, the ultra-high resolution of this three-dimensional finishing is perfectly suited for incorporating Braille text on infographic panels, ensuring both accessibility and aesthetic quality.

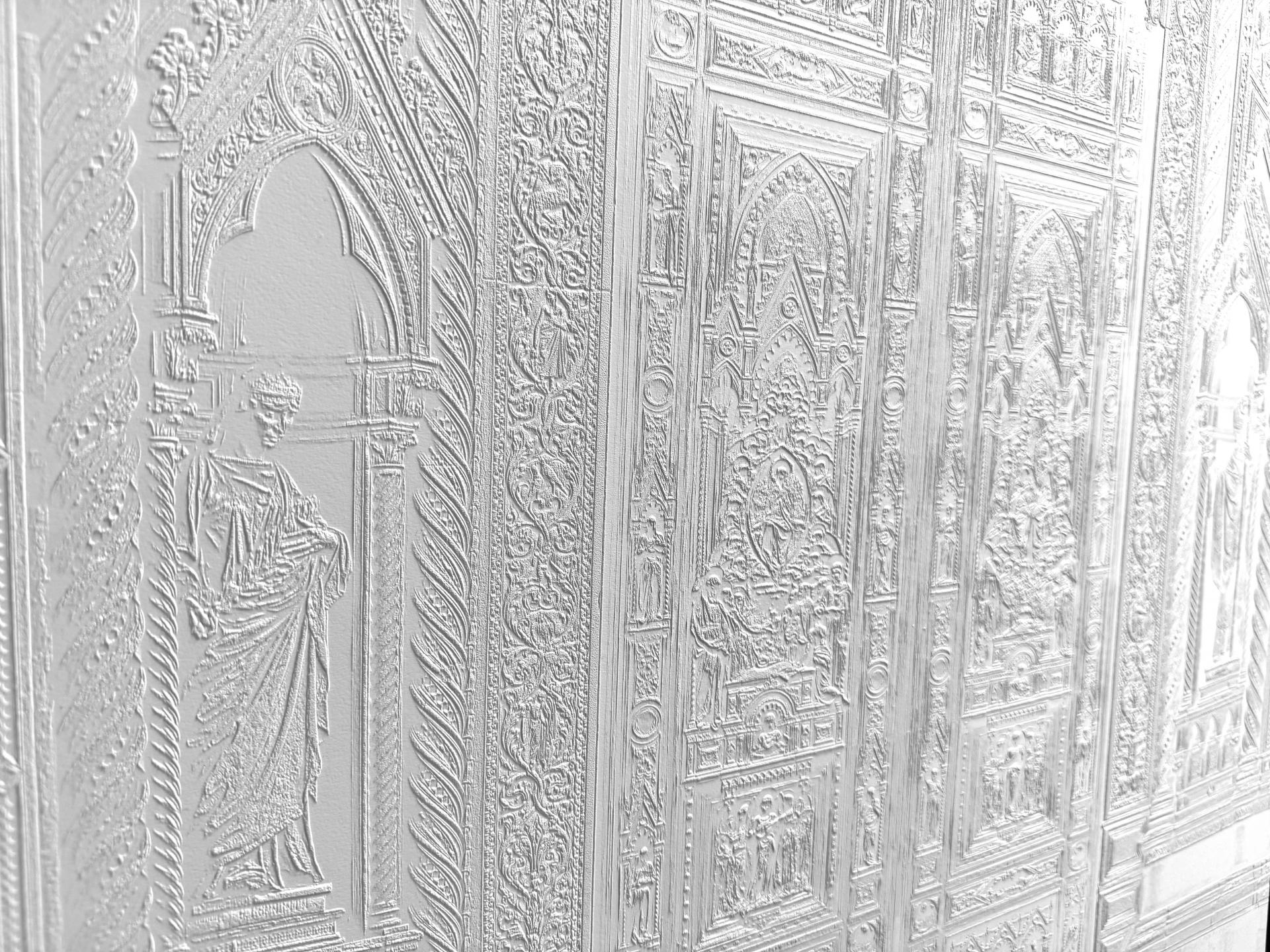

3D RELIEF PRINTS

After extensive testing, we have developed an exclusive method to impart extraordinary relief effects to fine art prints. Through a dedicated workflow, we extract a depth map from the images, which we then use to model the surface.

Our UV printer performs extremely precise and organic layering, creating a three-dimensional substrate onto which full-color printing is applied.

The result is 3D-relief prints—up to 124 × 249 cm—that convey texture, volume, and fine details in three dimensions.

This process makes it possible to give images an incredible material quality, making them even more immersive and three-dimensional. Moreover, since the pigments are crystallized using a UV lamp, the surface of the print will have excellent durability. This allows for the organization of true “tactile exhibitions.”

The applications of this unique printing system are virtually limitless, as it is perfectly suited for both the creation of photographic prints with relief effects and the reproduction of artworks. By shaping the printed surface, it is possible to recreate the painterly layer with its brushstrokes and craquelure.

The same applies to the creation of tactile and three-dimensional wallpapers capable of radically transforming interior spaces. Many interior designers have already entrusted us with the production of both art pieces and embossed wallpapers, which they have used to furnish spaces in a truly exclusive way.

As our examples illustrate, this solution is highly versatile—especially thanks to our “four‑hands” collaborative printing service with artists, allowing us to fully exploit the potential of this unique technology.

GLASS AND PLEXIGLAS

Direct UV fine art printing on glass and plexiglass enhances transparency and brilliance.

Thanks to opaque white ink, we can achieve opaline or semi-transparent effects, precisely modulating both clarity and density—even on complex surfaces.

Epson UltraChrome technology ensures strong adhesion and impeccable detail, with a halftone screen that is virtually invisible.

It’s possible to print on the reverse side of transparent materials using a white underlayer, resulting in a glossy front surface similar to fine art prints mounted under plexiglass. Alternatively, we can use matte transparent plexiglass for a satin finish.

Moreover, thanks to our ability to print on materials up to 8 cm thick, we can work with actual "blocks of plexiglass." This is particularly interesting, as it creates an effect similar to that of encapsulating images in ultra-transparent epoxy resin.

If the white ink is omitted, the result is a glossy yet translucent print in the highlights—reminiscent of photographic slides. This transparency is often used in multilayer artworks or when the piece is meant to interact with the surrounding space.

Direct UV printing on glass—or even better, on plexiglass—is also ideal for creating fine art lightboxes. By using multilayer printing, we can produce backlit images with exceptional depth and vibrancy, enhanced by a custom-designed LED lighting system specifically developed for this purpose.

One of the most interesting features of this type of lightbox is that the images remain visually appealing even when the backlighting system is turned off.

Since plexiglass is also available in both colored and fluorescent versions, it’s possible to create prints with highly interesting visual effects. By leveraging the background hues, one can achieve graphic patterns and transparencies that uniquely enhance each artwork. This approach is not limited to photography alone but is equally effective for contemporary art and graphic design pieces.

The maximum format is still 124 × 249 cm, and custom handcrafted frames allow for further personalization—especially for layered compositions.

STANDARD MATERIALS

Direct UV printing onto Forex, Dibond, and flexible vinyl delivers outstanding results. We utilize rigid substrates optimized for a perfectly flat surface, enabling vibrant color gamuts, rich blacks, and ultra‑high resolution—rendering fine details, text, and shapes with absolute precision.

The maximum format remains 124 × 249 cm, finished with handcrafted frames or aluminum spacers for wall installations.

These options are ideal for ultra‑high‑quality infographics or fine art prints for photographic exhibitions—suitable for both indoor and outdoor environments. UV‑cured prints are water‑resistant and offer strong protection against solar radiation

Additionally, both Dibond and Forex are ideal substrates for producing direct UV prints with 3D relief effects, thanks to their ultra‑smooth and ultra‑flat surfaces. This exceptional surface quality ensures maximum achievable detail without interfering with the image’s texture

| MATERIAL | CARACHTERISTICS | APPLICATIONS |

| Forex | Rigid expanded PVC foam board available in thicknesses of 3, 5, 10, or 20 mm. | Indoor Use, Temporary Exhibitions, and Infographics |

| Dibond | Compound alluminium available in thicknesses of 2 and 3 mm. | Outdoor Use, Photographic Exhibitions, Artworks |

| Vinyl | Lightweight Soft PVC Film or banner easy to installation and handling. | Banners, wallpapers, storefront displays, walkable surfaces, and infographics for both outdoor and indoor use. |

We recommend Dibond for producing prints intended to last over time or to be installed outdoors. This solution ensures perfect flatness and is almost essential for those who wish to display their works without frames. In fact, by simply applying an aluminum spacer to the back of UV direct prints on Dibond, they can be mounted directly on the wall using standard wall plugs.

Whether you choose to print directly on Dibond or on Forex, our handcrafted frames can be used to finish any format.

Forex, being an extremely lightweight and affordable material, does not offer the same flatness and durability as Dibond. For this reason, it is widely used for the creation of informational panels or infographics, which often accompany the main exhibition setup composed of fine art prints or direct prints on more suitable materials.

Direct UV printing on vinyl, while offering excellent resolution and quality, is especially suitable for the production of wall coverings or floor graphics, either for museum installations or interior design projects. Vinyl is an extremely flexible and lightweight material that lends itself perfectly to being coated with adhesive backing. In this way, it can be applied to any smooth, clean, solid, and stable surface. We often use it to create embossed "wallpapers" using multilayer printing techniques made possible by our UV printer.

METAL, ROCK AND OBJECTS

The ability to print on materials up to 8 cm thick opens up virtually endless possibilities: metal, stone, mirror, wood, and much more.

Metal printing enhances the natural reflectivity and texture of the surface: we have completed projects on iron, steel, copper, and gold leaf—even on oxidized surfaces or those with natural sedimentation. The images, carefully prepared according to the client’s wishes and specifications, retain all the distinctive qualities of the metal sheet, as they are printed directly onto the surface.

Unfortunately, industrial UV printing often comes with limitations: subpar resolution, inks that are either too opaque or too faint, and a general lack of fine-tuning capabilities. Our Fine Art UV printing, on the other hand, is not designed for mass production, but rather for precision and flexibility—tailored to the unique needs of each project. This allows us to produce true fine art prints even on complex surfaces such as metal, without any compromise.

Stone, too, lends itself to the creation of large-format works, where the materiality of the surface becomes an integral part of the visual language. Whether it’s pietra serena, marble, pumice, or even slabs of alabaster, we are able to deliver flawless prints—thanks to over fifty years of experience in fine art photographic printing, now applied to high-end direct printing.

These solutions are valuable tools for photographers, contemporary artists, interior designers, and architects.

Additionally, we can personalize objects such as tables, chairs, plastered surfaces, window glass, and mirrors—offering exclusive creative possibilities through our ultra-high-resolution UV printing technology.

These solutions are valuable tools for photographers, contemporary artists, interior designers, and architects.

In this context, we can customize objects such as tables, chairs, plastered surfaces, window glass, and mirrors, offering exclusive possibilities thanks to our ultra-high-resolution UV printing technology.

This allows for direct printing onto the surface of furnishings, fully respecting the nature of each material and achieving stunning results. Our Fine Art UV direct printing eliminates the need to print on paper or vinyl supports that then require adhesive application.

The result is a wide range of aesthetically flawless customizations, as the print is applied directly onto the object, combined with exceptional durability—surfaces can even be cleaned with a damp cloth.